Alloy Steel Forging

Alloy steel is made by adding elements such as chromium, nickel, or molybdenum to carbon steel, which improves strength, toughness, and wear resistance. Alloy steel forging is a manufacturing process that shapes alloy steel. The forging process refines the grain structure, making alloy steel components more durable and reliable than those produced by casting or machining.

Alloy steel offers several benefits when forged:

✔ Exceptional Strength & Toughness – Ideal for heavy-load applications.

✔ Improved Wear & Fatigue Resistance – Longer lifespan than standard steels.

✔ Customizable Properties – Alloying elements allow tailored performance.

✔ Superior Structural Integrity – Fewer defects compared to casting.

✔ Corrosion Resistance (in some grades) – Chromium and nickel improve durability in harsh environments.

The Alloy Steel Forging Process

Material Selection

Choose the appropriate alloy steel grade (e.g., 4140,4340, 8620) based on strength, toughness, and wear resistance requirements.

Heating

For hot forging, heat to 1,800°F–2,400°F (carbon-content dependent) to achieve optimal malleability.

Shaping

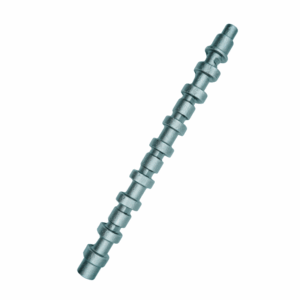

Open-die forging: Ideal for large, simple shapes like shafts and discs.

Closed-die forging: Used for complex, high-precision components like gears and turbine blades.

Roll forging: Suitable for elongated parts such as axles and levers.

Post-Forging Enhancement

Heat treatment (quenching & tempering): Enhances hardness and toughness.

Machining & surface finishing: Ensures dimensional accuracy and corrosion resistance.

Alloy Steel Forging Applications

Forged alloy steel components are prevalent in various industries.

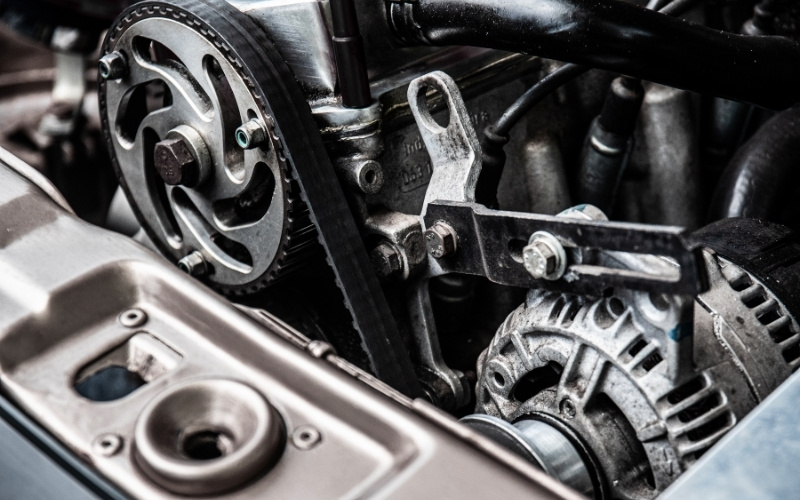

Automotive

Engine components, gears, and suspension parts are often forged from alloy steel for strength and durability.

Aerospace

Structural components and fasteners in aircraft require the enhanced properties of forged alloy steel.

Construction

Heavy-duty equipment and structural elements frequently utilize forged alloy steel for reliability.

Forged Alloy Steel Parts