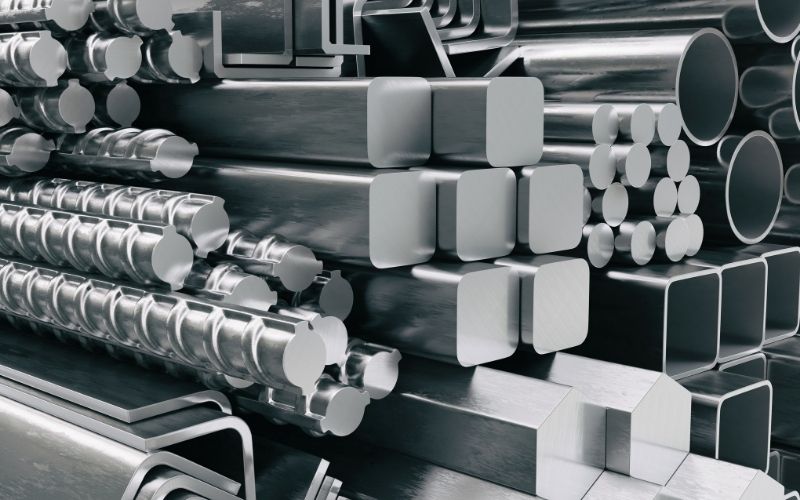

Stainless Steel Forging

Stainless steel is an alloy primarily composed of iron and chromium, with varying amounts of nickel and other elements. Forging stainless steel involves shaping the material under compressive force, resulting in components with enhanced mechanical properties and superior corrosion resistance.

Advantages of Stainless Steel Forging:

✔ Exceptional Corrosion Resistance – Ideal for harsh environments.

✔ High Strength-to-Weight Ratio – Durable yet easy to handle.

✔ Hygienic & Easy to Clean – Smooth surface makes it perfect for food/medical industries.

✔ Aesthetic Appeal – Polished finish suits diverse applications.

Stainless Steel Forging Process

Material Selection

Austenitic (304, 316), Martensitic (410), or Precipitation-Hardening (17-4PH) grades.

Heating

Hot forging at 1,700–2,300°F (927–1,260°C) prevents work hardening.

Shaping

Closed-Die Forging: Used for valves, flanges.

Open-Die Forging: Ideal for large shafts, rings.

Post-Forging Enhancement

Solution Annealing: Restores corrosion resistance.

Passivation: Removes free iron, enhancing rust resistance.

Applications of Stainless Steel Forgings

Forged carbon steel components are widely used across various industries due to their strength and reliability.

Automotive & Transportation

Used to manufacture high-strength and corrosion-resistant components.

Aerospace

Ideal for critical aircraft parts due to its excellent mechanical properties and corrosion resistance.

Construction

Oil & Chemical:

Employed in corrosion-resistant equipment and piping systems to ensure safety in harsh environments.

Power Generation & Metallurgy

Employed in corrosion-resistant equipment and piping systems to ensure safety in harsh environments.

Paper Industry

Applied in manufacturing hygienic machinery to prevent pulp contamination.